|

- What are your standard prototype PCB specifications?

- What kind of quality guarantee do you have?

- Can I cancel my order?

- How do I get a custom quote or place a non-standard order?

- How do I submit my design files?

- How do I avoid the most common errors?

- What file format do you accept?

- What files are needed for 2 layer boards?

- What files are needed for boards with more than 4 layers?

- What is the typical layer structure of 4-layer boards?

- What is the typical layer structure of 6-layer boards?

- What format do you prefer for inner plane layer, negative or positive?

- Do you want the bottom side Gerber files to be mirrored?

- What can I do if my board doesn't meet the standard specs?

- Can you make HDI and Blind/Buried via boards? What is your manufacturing capability?

- Can you make impedance-controlled boards?

- Can you accommodate non-plated hole designs?

- Do you have solder mask colors other than green?

- Do you have silkscreen colors other than white?

- Can you make boards with thickness other than 62 mils?

- Can you make boards with copper weight other than 1 oz?

- How much is extra charge for Immersion Gold finish and Lead-free Tin finish?

- How much is the extra charge for Gold Fingers?

- Can you do both side silk screens?

- Can you make internal routing? How much is the extra charge for internal routing?

- Can you make slot holes? Is there an extra charge for slot holes?

- Can you make tab routing? How much is the extra charge for tab routing?

- Do you accept Multiple Images or Step & Repeat? How much is the extra charge?

- Why is there an extra charge for Multiple Images or Step & Repeat?

- Can you do V-cut and what is its restriction?

- Are the drill sizes in design file the finished hole sizes or the tool sizes (before plating)?

- What drill sizes do you use?

- What is your confidential policy?

- What is your standard turn time? Do you offer faster turn time?

- What is your cut-off time and how do you calculate turnaround time?

- What is ITAR?

- What are your business hours?

- What shipping carriers do you use? How much is shipping cost?

- What if I have more questions?

| Q1. What are your standard prototype PCB specifications? | TOP |

Our standard prototype PCBs are 2 to 10 layer PCBs with the following specifications

| Material: FR-4 |

Thickness: 0.062 inch |

Copper weight: 1oz Inner/Outer |

| Min. trace and spacing: 6 mils |

Max. X or Y dimension: 16 inches |

Max. area: 160 sq. inches |

| Min. annular ring width: 7 mils |

Min. hole size: 12 mils |

Max. hole size: 244 mils |

| Max. Thru hole Aspect Ratio: 6:1 |

Min. SMD pitch: 18 mils |

Min. Solder Mask Bridge: 5mils |

| Board finish: Hot Air Solder Leveling

(HASL) |

Solder Mask: Green LPI (Both sides) |

Silkscreen: White Epoxy (Both sides if needed) |

Finished Drill sizes: From 10 mils to 22 mils with step of 4 mils; From 24 mils to 44 mils with step of 2 mils; From 48 mils to 244 mils with step of 4 mils;

From 244 mils up, any size with tolerance of +/-6mils (By routing).

|

|

For 4-10 layer PCBs: The Min. spacing from the hole-edge to hole-edge is 15mils; the Min. spacing from the hole-edge to circuit pattern is 7mils for Outer layers/10mils for Inner layers; The Min. spacing from board outline to circuit pattern.

|

| All holes will be plated in our standard prototype PCBs unless you specify non-plated holes when you place the order.

|

| Note1: For Gold Fingers, Gold Plating, RoHS compliance finish, Internal Routing, Complex routing, 2oz /3oz Copper weight and Board thickness of 79mils up, extra charges will apply. Extra one day might be needed for some non-standard specs. |

| Note 2: For Rogers board or Blind/Buried Vias, please ask for a custom quote by sending email to order@PCBex.com. |

| Q2. What kind of quality guarantee do you have? | TOP |

We are committed to deliver you high-quality PCBs at low price. Our manufacturing facility is ISO-9001:2000 certified and every board is inspected by a well-trained QA person. If your PCBs do not meet the specifications due to mistakes on our part, we will remake them immediately for no charge.

| Q3. Can I cancel my order? | TOP |

Generally you cannot cancel your order because we process it right away once your order and files are submitted to ensure on-time delivery. You could check with us before 6:00PM central time on the same day you placed the order. In case the order has not gone to production, we can cancel it without any charge. If you cancel your order before we ship it, we can refund the shipping cost but all the other charges will be applied to your credit card.

| Q4. How do I get a custom quote or place a non-standard order? | TOP |

If you want to place a large volume order (We provide more discount for volume orders), you can ask for a custom quote by sending your zipped Gerber 274X files and NC Drill file with a detailed description to support@PCBex.com. Please include your contact information in the email. Our representative will get back to you promptly. You can also call our friendly customer representative at (713) 436-7688. If you want to place a non-standard order, please select the non-standard specs carefully.

| Q5. How do I submit my design files? | TOP |

After you place your order online, please upload your zipped Gerber File online immediately. If you have trouble in file uploading, please email your Gerber274X files promptly to order@PCBex.com, with your order number in the subject line. Please include the file name, quantity and any special requirement in the email. If there is no special requirement in the email or in online order record, the PCB board will be fabricated according our standard specs.

| Q6. How do I avoid the most common errors? | TOP |

In order to process your order smoothly and avoid your order being on-hold, you can take the following steps to avoid the most common errors:

- Ensure all your files are readable and all needed files are included. Refer to Q8 & Q9 for the needed files. Double-check your files for design errors.

- Ensure all your files are readable and you design meets our standard specs: 0.062" thickness, 1oz copper, HASL finish, 6mil/6mil trace width/space, 12mil min. hole, 6mil min. annular ring, and 5mil min. silkscreen line width, 40mil char height etc. We recommend you to review the Gerber files and NC Drill file with free Gerber viewer ViewMate. You can download it at: http://www.pentalogix.com/Download/download.html

- Ensure Gerber files are 274-X format, not 274-D format, and the aperture list is included in Gerber 274X files. NC drill file is in ASCII format.

- Ensure the board outline is on an outline layer or any other layer.

- If you intend to use our standard specification to take advantage of online promotion prices, ensure there is no discrepancy between your fabrication notes and our standard specs. You could add “standard specs” in customer notes/comments field.

- If you have special request or your design does not meet standard specs, please include all construction information in the fabrication drawing or Readme file.

Our standard PCB prototypes are expected to have all plated holes. However, if you specify non-plated holes, we can process the order for an extra charge of $12 per order. Refer to Q16.

| Q7. What file format do you accept? | TOP |

In Standard Prototype, we accept Gerber files in 274-X format, NC Drill files in Excellon format. If your Gerber files are in 274-D format, aperture file must be provided for each layer.

| Q8. What files are needed for 2 layer boards? | TOP |

Gerber files of artwork and NC drill file are needed for PCB fabrication. For 2-layer PCB, Gerber files usually include Top Copper, Top Solder Mask, Top Silkscreen, Bottom Copper, Bottom Solder Mask, Bottom Silkscreen if needed, and outline layers if not included in the other layers; NC Drill file in Excellon format with tool sizes is needed for drilling holes; The layers corresponding to file names should be obvious, otherwise they need to be specified in the email or Readme file.

| Q9. What files are needed for boards with more than 4 layers? | TOP |

PCB’s with 4 layers or more require all file types needed for 2-layer PCB, plus the inner copper layers. The layer stack-up sequence needs to be specified in the Readme file or email.

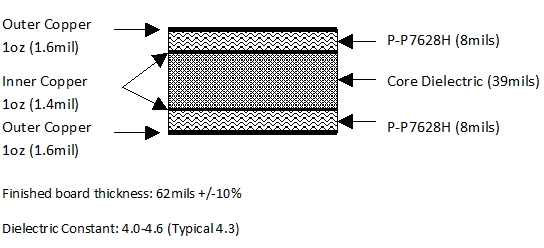

| Q10. What is the typical layer structure of 4-layer boards? | TOP |

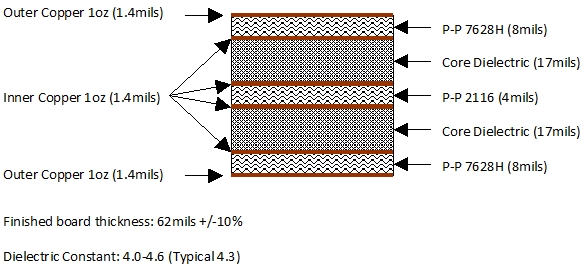

| Q11. What is the typical layer structure of 6-layer boards? | TOP |

| Q12. What format do you prefer for inner plane layer, negative or positive? | TOP |

For inner plane layers, if it is power plan or ground plan, we prefer Negative format, because it makes file size smaller, easier to transfer and process. However, if it contains circuits, you can keep it as positive layer.

| Q13. Do you want the bottom side Gerber files to be mirrored? | TOP |

No, please generate all the Gerber files seen from Top.

| Q14. What can I do if my board doesn't meet the standard specs? | TOP |

If you want to place the order with non-standard specs, like 2oz copper, immersion gold, please check the non-standard specs items carefully. There is small amount of extra charge for non-standard specs.

We will process the order with the special requests that you paid for. You could also ask for a custom quote by sending email to order@PCBex.com

| Q15. Can you make HDI and Blind/Buried via boards? What is your manufacturing capability? | TOP |

Yes, we can make HDI boards with min. trace width/space of 3mils and min. hole size of 6mils. We can also make Blind/Buried via boards. Please ask for a custom quote for the special order.

| Q16. Can you make impedance-controlled boards? | TOP |

Yes, we can make impedance-controlled boards. Please ask for a custom quote.

| Q17. Can you accommodate non-plated hole designs? | TOP |

Our standard PCB prototypes are expected to have all holes plated. However, if you choose non-plated holes in your online order or custom order, we can process orders with non-plated holes with an extra charge of $12 per order. Please have the non-plated holes defined clearly in your zipped Gerber file or readme file.

| Q18. Do you have solder mask colors other than green? | TOP |

Yes, we have green, red, blue, black, and white solder masks. There is an extra charge of $20 per order for solder masks other than green.

| Q19. Do you have silkscreen colors other than white? | TOP |

Yes, we have red, blue, and white silkscreen colors. There is an extra charge of $20 per order for silkscreen colors other than white.

| Q20. Can you make boards with thickness other than 62 mils? | TOP |

In our standard Prototype, the board thickness is 62 mils. We can also make boards with thickness of 24 mils, 31 mils, and 47 mils with an extra charge of $30 per order, and boards with thickness of 78 mils or above with min. extra charge of $40 for 2-layer prototype, depending on the total area size.

| Q21. Can you make boards with copper weight other than 1 oz? | TOP |

In our standard Prototype, finished copper weight is 1oz inner/1oz outer. We can also make boards with copper weight of ½oz, 2oz, and 3oz. There is an extra charge of $20 for ½oz and min. extra charge of $30 per order for 2oz copper, and $60 for 3oz copper, depending on the total area size.

| Q22. How much is extra charge for Immersion Gold finish and Lead-free Tin finish? | TOP |

There is an extra charge of $50 or more for Immersion Gold finish, and $30 for Lead Free finish, depending on the total board area.

| Q23. How much is the extra charge for Gold Fingers? | TOP |

There is min. extra charge of $50 per order for Gold Fingers plating.

| Q24. Can you do both side silk screens? | TOP |

If you need both side silkscreens, we can make it for you free. You need to choose two sides silkscreen when you place the order.

| Q25. Can you make internal routing? How much is the extra charge for internal routing? | TOP |

Yes, we can make internal routing. If it is very simple internal cut-outm we will make it for you free of charge. Please make sure to add “internal cut-out needed” in customer notes/comments field. There will be an extra charge of $30 or more per order for complicated internal routing.

| Q26. Can you make slot holes? Is there an extra charge for slot holes? | TOP |

We can make up to 5 slot holes for you free if you clearly draw them in the design files and the slot hole width needs to be at least 40mils. If there are more than 5 slot holes, there will be an extra charge of $30 or more per order, depending on the total price.

| Q27. Can you make tab routing? How much is the extra charge for tab routing? | TOP |

Yes, we can make tab routing; there will be an extra charge of $50 or more per order, depending on the complexity.

| Q28. Do you accept Multiple Images or Step & Repeat? How much is the extra charge? | TOP |

In general, the standard online prices do not apply to orders with multiple images or Step & Repeat. If you place an order with Multiple Images or Step & Repeat on the layout, there will be an extra charge, depending on the number of layers and images, in addition to the total board price, e. g. $30 for each additional image or Step & Repeat for 2-layer board. You could also request a custom quote by sending email to order@PCBex.com

| Q29. Why is there an extra charge for Multiple Images or Step & Repeat? | TOP |

Please understand that all the prototype boards involve file review, setup, film making, and more than 20 steps of process. It takes extra work to process an order with multiple images. We don't encourage designs with multiple images, but if you want to save some money, we can make it for you with a little compensation.

| Q30. Can you do V-cut and what is its restriction? | TOP |

Yes, there is an extra charge of $50 per order for panel with V-cut and $30.00 per order for panel without V-cut. The Min. panel size is 0.44" x 0.4", Max. Panel size is 16" x 10", Min. Groove to Groove width is 0.4"; V-cut angle is 45 degrees; Groove width is 20mils, V-cut should be from edge to edge (No jump scoring). If you don't know how to make the best way for V-cut, you could send the single Gerber file to us and we will make it for you.

| Q31. Are the drill sizes in design file the finished hole sizes or the tool sizes (before plating)? | TOP |

The drill sizes in the NC drill file are finished hole sizes. The actual tool sizes we use are approx. 2 mils larger than the finished hole sizes since there is approx. 1 mil thick copper-plated wall in the holes.

| Q32. What drill sizes do you use? | TOP |

Finished drill sizes from 10 mils to 22 mils with step of 4 mils, from 24 mils to 44 mils with step of 2 mils, and from 48 mils to 240 mils with step of 4 mils. For hole size larger than 240 mils, we use routing instead of drilling, the tolerance is +/- 3mils. But no more than10 of holes larger than 240mils are allowed on a single board. Boards with finished hole sizes smaller than 10mil and larger than or equal to 8 mil will considered as high density board (HDI), and there is an extra charge for HDI.

If the finished hole size is not the exact size we can make, we will round it up to the closest one with maximum deviation of 2 mils. Usually the difference can be neglectable. As long as your hole sizes are within the specified range, usually there is no problem with it.

| Q33. What is your confidential policy? | TOP |

PCBex will hold every customer's design files and other confidential information in strict confidence. We will not disclose such files and confidential information to any third parties, and will not use such files and confidential information for any purpose except for the customer's PCB fabrication.

| Q34. What is your standard turn time? Do you offer faster turn time? | TOP |

Our standard turn times are 5 business days for 2-layer PCB, 7 days for 4-layer PCB, 8 days for 6-layer PCB, 8 days for 8-layer PCB, and 10 days for 10-layer PCB. We also offer expedited turn time with extra charge. Expedited turn times are 3 days for 2-layer PCB, 5 days for 4-layer PCB, 5 days for 6-layer PCB, 6 days for 8-layer PCB, and 8 days for 10-layer PCB. If you want turn time faster than the expedited turn time, please send your request to order@PCBex.com. Please include your Gerber file, turn time desired, quantity an any non-standard specs in your email. Please make sure your Gerber files are correct. We make your boards based on your design files. In case we find obvious and significant errors, we will contact you and the turn time will be counted from the day when problems are solved.

| Q35. What is your cut-off time and how do you calculate turnaround time? | TOP |

We calculate the turn time from the cut-off time, which is 6:30 PM Central Time on each business day. For example, if you have a 5 day turn time order that comes in on Tuesday before 6:30 PM, then your order will be shipped on the next Tuesday if there is no holiday during the turn time. If the total area size>=3,100 in^2 or Qty > 500pcs, the standard turn tie will be 10-day up for 2 & 4 layer PCB; adn15-day up for 6 &8 layer PCB.

(International Traffic in Arms Regulations) U.S. State Department regulations that govern the export of restricted technology to foreign states other than Canada. If your board design data is ITAR-controlled, please inform us when you place your order. For more information on ITAR, please go to http://en.wikipedia.org/wiki/ITAR or http://pmddtc.state.gov/.

| Q37. What are your business hours? | TOP |

9:00AM to 6:00PM Central Time, Monday through Friday.

| Q38. What shipping carriers do you use??How much is shipping cost? | TOP |

Currently we use FedEx for prototype PCB delivery to the US or Canada. We use FedEx or DHL for production order delivery to the US or Canada. There is min. charge of $20 to the US and $22 to Canada for shipping and handling.

| Q39. What if I have more questions? | TOP |

Send email to support@PCBex.com or call customer service at (713) 436-7688.

|